Gasket rubber seals are an important component that we meet in many machines and various machinery. They are seals that are essential in preventing leaks and maintaining cleanliness. In so doing, they take care that everything is going smoothly and efficiently. This article journey will take you through what gasket rubber sealing strips are, why are they so important, and how are they used extensively across various industries? We’ll also explain which Boman gasket rubber seal to select for your project and other tips on installing and maintaining it in good condition so it can last.

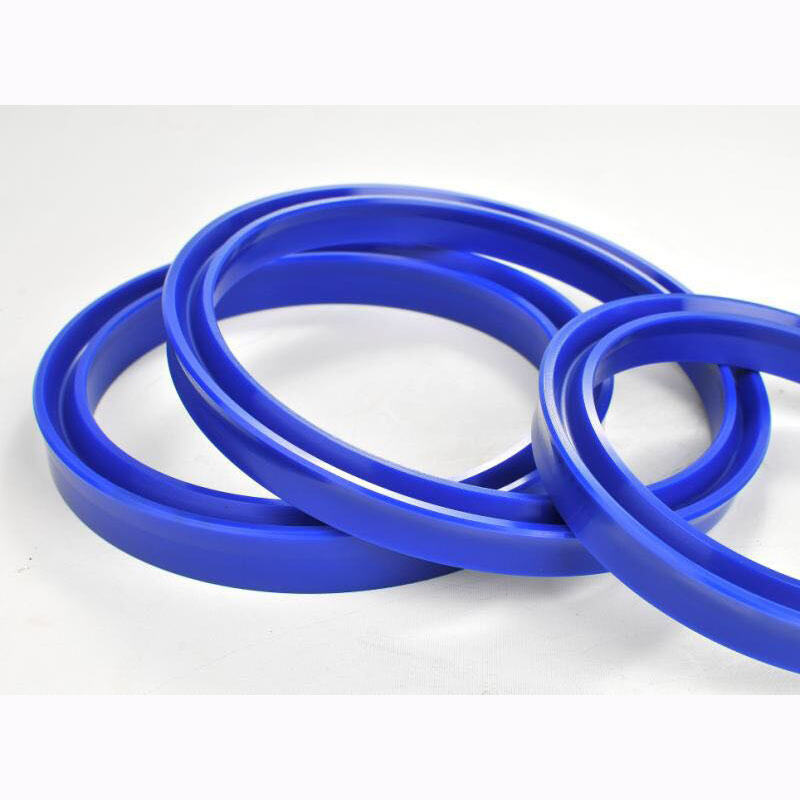

What Are Protective Gasket Rubber Seals? They prevent liquids or gases from spilling out of machines. To appreciate their significance, consider having a water bottle that has a hole in it. If that were to happen, the water would go everywhere and create a great mess! It is gasket rubber also creates a strong, tight seal that prevents leaks from occurring. This makes the machines more efficient and increase their longevity.

Gasket rubber seals from Boman are used in factories and should be used in other places too with all the machines as rubber seals for gaskets to ensure a perfect seal. These seals should avoid machine breakdowns, as that can be expensive, time-consuming, and even unbearable. When machines fail, they can take a huge amount of time to fix, and until that happens, companies may not be generating money. Gasket rubber seals also save businesses time and money in repairs and replacements. Workers can also do their jobs without interruptions, which is essential to keeping production running.

There are so many types of gasket rubber seal and choosing the right one is crucial. There are different types based on the needs of the project you are working on. Some seals are better in high-temperature situations, while others are preferable to be used with harsh chemicals. Selecting the proper kind of neoprene gasket rubber seal, that can be effective and long-lasting, is of utmost importance. Choose the wrong one and it can result in leaks or other issues, which can be really annoying.

Once you have selected the appropriate Boman gasket rubber seal for your project, the next step is to ensure proper installation. This is a truly critical element of the process. It is important to ensure that the surfaces have been cleaned where you are going to apply the seal, as dirt or old materials may prevent it from working properly. Next, gently place the seal to ensure a snug and secure seal. Regular maintenance is also critical for ensuring the gasket rubber seal continues working correctly as time goes by. Regularly checking the seal for wear and tear can help nip any issues in the bud before they become serious problems.

Gasket rubber seals serve one of the most important functions to contain leaks and contamination. Without these seals, machines and equipment may leak hazardous chemicals or fluids. It damages the machines and poses a threat to the environment and people's health. The Boman window gasket rubber seals are crucial to ensure everything is safe and leak-free, which is important for safety and regulation;