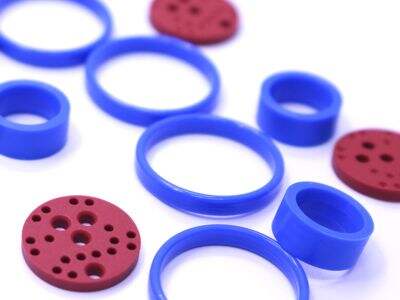

Hi ha molts factors a considerar quan es busca un proveïdor de peces d'escuma de goma personalitzades, i és útil disposar d'una llista de comprovació que guiï el procés de presa de decisions. Boman pot apreciar la importància de subministrar peces de qualitat a diversos sectors. Alguns dels punts clau a tenir en compte mentre cerca un proveïdor

Trobada del fabricant adequat de peces d'escuma de goma personalitzades

Trobar el millor proveïdor de peces d'escuma personalitzades pot ser una tasca difícil, però hi ha diverses maneres efectives de localitzar empreses fiables. Una de les primeres coses que faria seria començar a investigar en línia. Hi ha molts proveïdors amb llocs web on es mostren els productes i serveis oferts, així com la seva trajectòria professional. Ezra Siegel ha demostratEscriure almenys 5 dies diferents en altres dates del calendari Podem assistir a fires sectorials i exposicions on es pot conèixer en persona possibles proveïdors. També és una excel·lent manera d’obtenir bones recomanacions posar-se en contacte amb altres professionals del teu sector. A més, existeixen motors de cerca locals i directoris específics del sector que pots utilitzar per trobar proveïdors propers. Mitjançant aquestes diferents vies pots acumular una llista de proveïdors potencials per revisar i, possiblement, seleccionar per al teu de goma moldada a mida projectes de peces

Problemes típics en l'adquisició de peces d'escuma personalitzades

Tot i que els compradors intenten trobar el proveïdor òptim de peces personalitzades d'estrat de goma, encara poden trobar-se amb alguns problemes habituals durant aquest procés. Un problema comú és que la qualitat de les peces compleixi amb els estàndards necessaris. És important tenir en compte el procés de fabricació dels proveïdors, els seus protocols de control de qualitat i certificacions per garantir que les peces siguin fiables i duradores. El preu també és un factor clau, ja que els compradors han de sospesar el cost bàsic respecte a la qualitat de la peça. La transparència i recursos eficaços de comunicació són crítics en cas que es presentin problemes en l'adquisició. Definir clarament les expectatives, termes i condicions, entregables i terminis amb el proveïdor ajudarà a minimitzar malentesos i facilitarà la col·laboració. A més, els temps logístics i els plazos de lliurament són factors essencials, especialment en sectors amb cicles de disseny superiors als 6 mesos o aquells amb urgència contractual o de lliurament. Sent reactius davant aquests problemes habituals i mantenint oberts els canals de comunicació amb el proveïdor, els compradors poden adquirir amb èxit al mercat mundial el que necessiten

Si esteu buscant un proveïdor de peces d'escuma personalitzades, cal tenir en compte alguns aspectes clau per garantir que trobeu els productes adequats i que siguin de la màxima qualitat. Aquestes són algunes coses a considerar quan seleccioneu el millor proveïdor per a les vostres peces d'escuma personalitzades

Selecció d'una font de peces d'escuma personalitzades

Feu la vostra recerca i compareu ofertes: Abans de decidir-vos per un proveïdor, dediqueu temps a investigar diverses empreses i a comparar les seves ofertes (productes, preus, opinions). Feu negocis amb proveïdors ben coneguts i amb molta experiència en el sector

Qualitat i proves: Comproveu que el vostre proveïdor disposa d'un programa sòlid de control de qualitat per verificar que les vostres peces d'escuma personalitzades compleixin els vostres requisits i estàndards

Comunicació: No voleu quedar ignorat quan necessiteu discutir detalls sobre el vostre producte de marca pròpia i/o fabricació per contracte durant el seu desenvolupament. Una comunicació oberta és essencial per obtenir allò que voleu

Com triar proveïdors de peces d'escuma de goma personalitzades

Sol·liciteu mostres: un cop hagueu avaluat la qualitat i el rendiment del producte, demaneu al fabricant que us proporcioni mostres dels seus de goma moldada a mida peces

Verifiqueu les certificacions: assegureu-vos que el fabricant estigui certificat i qualificat per fabricar components d'escuma de goma personalitzats. Això us pot ajudar a garantir que compleixin els estàndards i regulacions del sector

Servei al client: considereu el servei al client del proveïdor i la rapidesa amb què respondran. El criteri ideal per a un proveïdor és aquell amb qui podeu col·laborar fàcilment i que respongui als problemes de manera oportuna perquè res no entorpeixi el procés de fabricació

Adquisició de peces d'escuma de goma personalitzades: consideracions clau

Material: reviseu les opcions de material per a peces d'escuma de goma personalitzades i assegureu-vos que siguin compatibles amb la vostra aplicació

Capacitat de producció: Assegureu-vos que el proveïdor tingui la capacitat de produir el que necessiteu, quan ho necessiteu. Combineu els vostres pedidos amb un proveïdor d’alt volum. Un fabricant que pugui gestionar eficientment els vostres pedidos gràcies a una línia de producció extensa

Preu: El preu és un factor a considerar, però no l'únic determinant en triar un proveïdor. El cost s'ha de justificar amb la qualitat i el servei del proveïdor, així que compareu ofertes per obtenir el millor tracte

Utilitzeu aquests consells i enteneu aquests criteris per trobar un proveïdor reputat de de goma moldada a mida peces que compleixi els vostres requisits. Boman es dedica a oferir peces personalitzades d'elastic moldat i un servei al client superior per a la indústria manufacturera

El contingut

- Trobada del fabricant adequat de peces d'escuma de goma personalitzades

- Problemes típics en l'adquisició de peces d'escuma personalitzades

- Selecció d'una font de peces d'escuma personalitzades

- Com triar proveïdors de peces d'escuma de goma personalitzades

- Adquisició de peces d'escuma de goma personalitzades: consideracions clau